What Is Concurrent Engineering

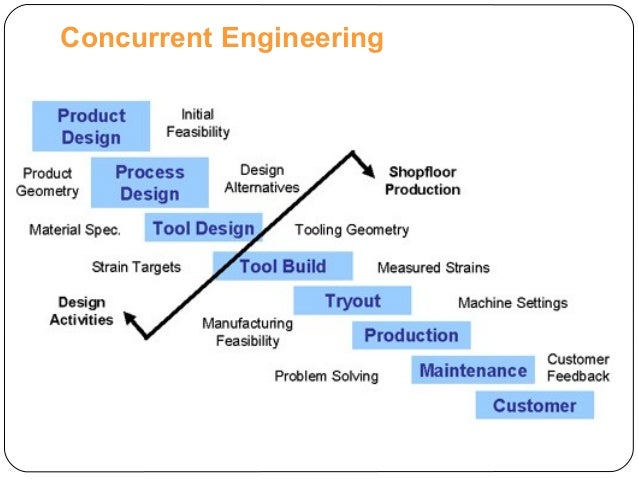

Concurrent Engineering. Tweet: A method of simultaneously designing products, and the processes for manufacturing those products, through the use of cross functional teams (representatives from many different departments, suppliers and customers), to assure manufacturability, lowest lifecycle costs, and to reduce overall development.

PCB Assembly

Our printed circuit board assembly capabilities can provide you with immediate prototype turnaround and on-time delivery of small to large production volumes for any single or double-sided printed circuit board configuration, including plated through hole, surface mount and mixed technology. We maintain complete lines of electronics assembly, inspection, cleaning, in-circuit and functional testing equipment to ensure that finished product conforms to customer requirements.

Learn MoreCable Assembly

Concurrent Manufacturing Solutions is a premier custom manufacturer for cable assemblies, harnesses and custom molded cable products, with an emphasis on value added service and support. Concurrent Manufacturing Solutions success has been based on supplying a cost-effective combination of product quality, engineering support, manufacturing responsiveness and business flexibility.

Sheet Metal Fabrication

Our sheet metal fabrication facility is positioned to support all production needs from rapid prototyping through volume manufacturing. Using the latest state-of-the-art design tools, we can accept design files from all major CAD system formats to analyze your product in detail. At Concurrent Manufacturing Solutions, our skilled technicians use MIG, TIG and resistance welding equipment to weld a wide range of materials, from very light gauge to heavy gauge precision products.

Learn MoreIntegration & Boxbuild Services

Concurrent Manufacturing Solutions has a broad contract manufacturing offering which complements our box build assembly capability. With our unique mix of metal fabrication, welding, electronics, electrical and top-end configure-to-order assembly/integration services, we partner with OEMs who desire top quality and competitive pricing and maximum flexibility.

When you need to get the most from your manufacturing, it is vital to hone your production processes. The more efficient and speedy your work, the more benefits you’ll provide to your company as a whole.

In terms of processes, concurrent engineering is definitely worth your while.

To learn the ins and outs of this manufacturing process and why you should look into it for your company, keep reading.

What Exactly Is Concurrent Engineering?

This is a manufacturing process that you’ll be glad to adopt. It involves doing multiple projects simultaneously while working on a singular project.

Concurrent engineering means all hands on deck with the professionals you staff to complete a project.

What Makes the Process so Advantageous?

There are several reasons that this process of engineering is popular in a lot of different industries. Companies that practice concurrent engineering enjoy the benefits below and then some:

1. You’ll Be Able to Speed up Your Production

Too many cooks only spoil the broth when they’re not all headed in the same direction.

With concurrent engineering, the production plan is mapped out far in advance. As a result, every professional putting the separate pieces of the puzzle together are all working toward the same goal.

This yields speedy production times, which also means you get the product to market much more quickly. You’ll boost your bottom line as a result, and can make the most effective use of your time and resources.

2. Your Products Will Be of Higher Quality

By having a more organized production process, you’ll find that you also make fewer mistakes.

You’ll have better odds of producing a quality product without defects. As a result, you’ll receive fewer returns and recalls, and can build a strong rapport among your consumers.

Concurrent production allows for better quality control since more sets of eyes mean more chances to catch mistakes along the way.

3. The Professionals You Staff Will Gain More Experience and Versatility

Finally, you’ll also have more highly-trained staff when you use this form of engineering.

This is because each professional will have to learn how to do multiple tasks. Everyone will be more well-rounded, which also means they’re able to help you out in new and different ways.

What Is Concurrent Engineering Pdf

You’ll receive fewer setbacks no matter what staff members show up since everyone is trained in the same areas of expertise.

But, make sure that the training is thorough and detailed so that they’re able to operate every task with focus and diligence.

Continuously Hone Your Production Processes

No matter what sort of products you create, concurrent engineering is worth your time to consider. It’s a process that will help you make the most out of your company, so you should consider adopting it.

If you need a set of engineers to help you out with this process, you can’t go wrong getting in touch with us.

Keep checking out our blog posts and find out more about our approach and how we can help you.